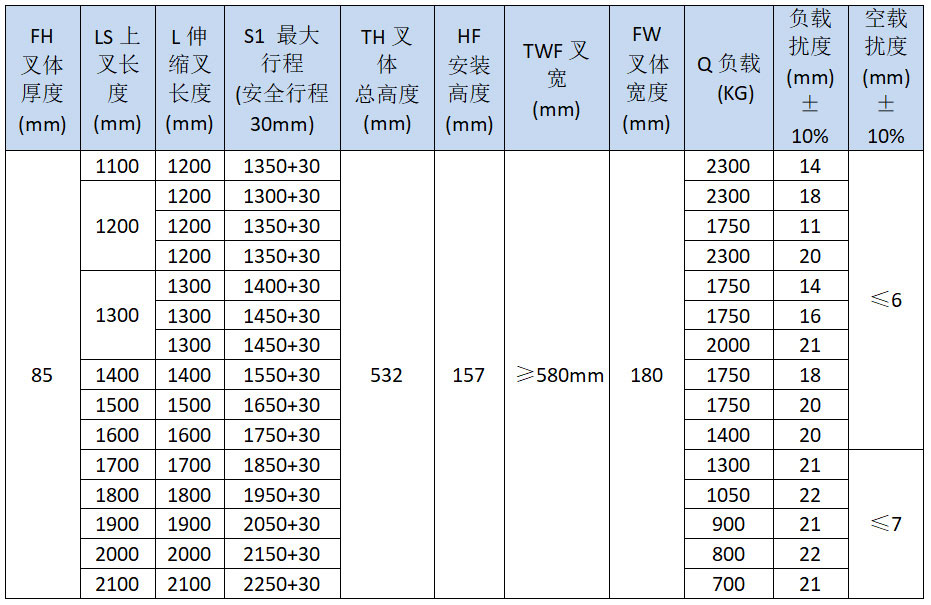

The HFTB180x85 series of single reach forks is a reinforced version of the HFTA180x80 series with increased load carrying capacity. This series of fork is mostly used for 1750kg-2300kg standard pallet storage in automatic three-dimensional warehouse.

Main components and functions:

1. one-piece upper fork: made of high-strength plate with overall bending, simple and beautiful, high strength. 2. high-strength needle bearings;

2. high-strength needle roller bearings: customized according to the requirements of telescopic fork industry, with high precision, low resistance, strong radial bearing capacity, high hardness and self-aligning function, wear-resistant and impact-resistant. 3. polymer guiding block: ultra-polymer material guide block, with high precision, low resistance and high strength;

3. polymer material guide block: ultra-high polymer polyethylene, high wear-resistant, impact-resistant, self-lubricating; 4. analyzer chain: tensile resistance, high strength, high destructive load, fatigue-resistant;

5. one-piece center fork: made of high quality steel, one-piece molding by machining center, with high precision;

6. Torque limiter protection: the driving part is equipped with a torque limiter, disc spring friction plate structure, overloading when slipping timely disconnect transmission;

7. Mechanical limit protection: the telescopic fork is equipped with mechanical limit inside to prevent over-travel out;

8. Drive: frequency conversion motor, AC servo motor with planetary reducer and other ways to provide driving force;

Main parts and functions:

1. One-piece upper fork: made of high-strength plate overall bending processing, simple and beautiful, high strength;

2. high-strength needle roller bearings: customized according to the requirements of telescopic fork industry, with high precision, low resistance, strong radial bearing capacity, high hardness and self-aligning function, wear-resistant and impact-resistant. 3. polymer guiding block: ultra-high polymer polyethylene, high wear-resistant and impact-resistant;

3. polymer material guide block: ultra-high polymer polyethylene, high wear-resistant, impact-resistant, self-lubricating; 4. analyzer chain: tensile resistance, high strength, high destructive load, fatigue-resistant;

5. one-piece center fork: made of high-quality steel, one-piece molding by machining center, with high precision;

6. Torque limiter protection: the driving part is equipped with a torque limiter, disc spring friction plate structure, overloading when slipping timely disconnect transmission;

7. Mechanical limit protection: the telescopic fork is equipped with mechanical limit inside to prevent over-travel out;

8. Drive: frequency conversion motor, AC servo motor with planetary reducer and other ways to provide driving force;